From Setup to Success: How to Master Direct-to-Film Printing

Direct-to-Film (DTF) printing is revolutionizing the custom apparel and merchandise industry.

With its ability to print high-quality designs on a variety of fabrics quickly and cost-effectively, DTF printing is becoming the go-to method for businesses looking to expand their product lines.

If you’re considering entering the world of DTF printing, mastering the process from setup to execution is key to running a successful operation.

In this article, we will guide you step-by-step on how to master DTF printing, from setting up the equipment to scaling your business.

Understanding DTF Printing and Its Benefits

Before diving into the technical aspects of DTF printing, it’s essential to understand what makes this process unique.

Direct-to-Film printing involves printing a design onto a special transfer film, which is then transferred to the fabric using a heat press.

Unlike traditional methods like screen printing, DTF printing can handle complex, multi-color designs, making it ideal for custom apparel.

One of the biggest advantages of DTF printing is its versatility. It allows you to print on a variety of materials, from cotton and polyester to leather and nylon, making it perfect for t-shirts, hoodies, bags, and even promotional items like hats.

Additionally, DTF printing is cost-effective for small batch orders, which is a significant benefit for small businesses or those just starting out.

Step 1: Setting Up Your DTF Printing Equipment

Setting up your DTF printing equipment properly is crucial for achieving high-quality results. You’ll need the following essential equipment to get started:

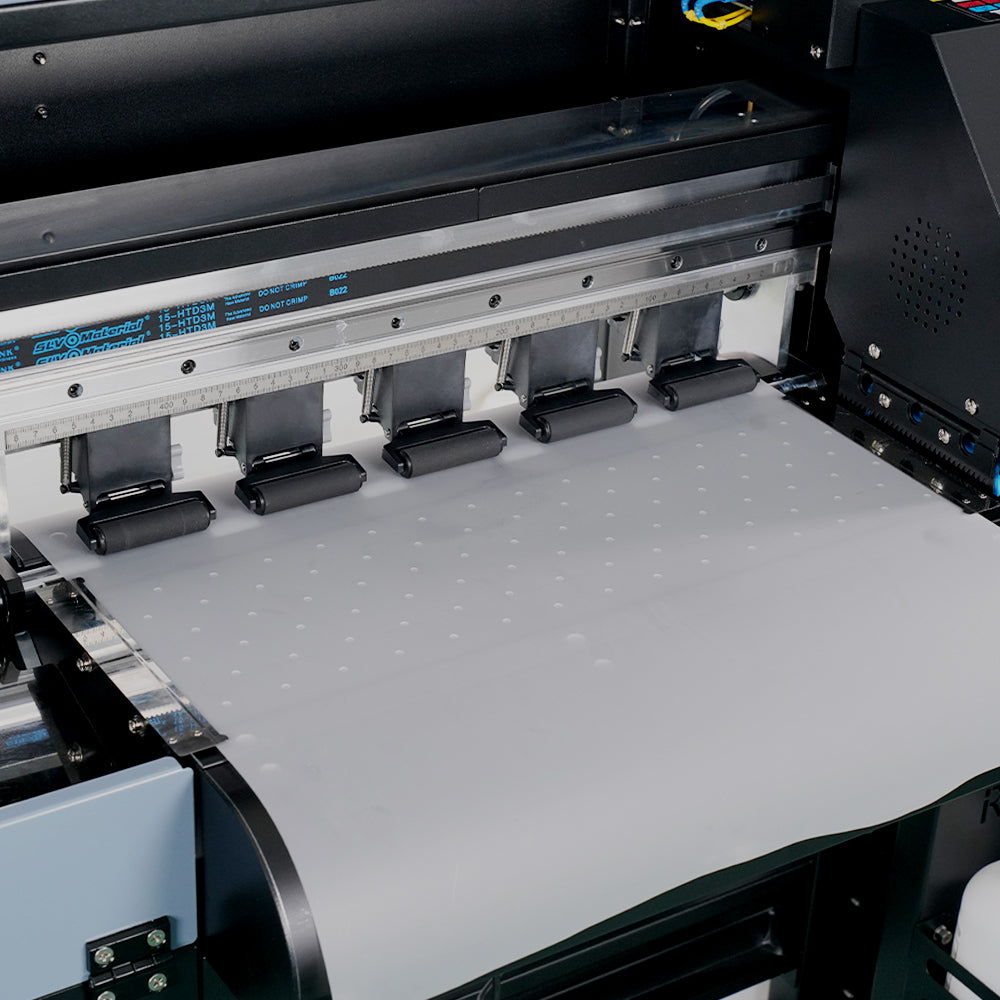

- DTF Printer: The heart of the process is the DTF printer, which uses specialized water-based inks designed for film printing. When choosing a printer, consider the print resolution and size to ensure it meets your business needs.

- Transfer Film: DTF transfer films are coated with a special layer that allows the ink to adhere correctly. This film is essential for transferring designs onto fabric.

- Adhesive Powder: After printing the design onto the transfer film, an adhesive powder is applied to help the design bond with the fabric when heat-pressed.

- Heat Press: A heat press machine is used to apply the transfer to the fabric. The heat and pressure help the design bond with the material, ensuring a long-lasting result.

- Curing Equipment (optional): Some setups may require a curing oven to fully set the ink and adhesive powder before heat pressing.

When setting up, make sure that all equipment is placed in an organized manner, ensuring easy access and smooth workflow. A clean, well-lit workspace can improve both efficiency and the quality of your prints.

Step 2: Preparing Your Design for DTF Printing

Preparing your design is one of the most important steps in the DTF printing process. The quality of your design directly impacts the final result. To ensure your design looks sharp and vibrant, follow these steps:

- Resolution and File Format: Use high-resolution images (at least 300dpi) to avoid pixelation. Common file formats such as PNG, TIFF, and PSD are ideal for DTF printing because they preserve transparency and image quality.

- Design Software: Programs like Adobe Illustrator, Photoshop, and CorelDRAW are popular choices for creating and editing designs. Make sure your design is in CMYK color mode to ensure accurate color reproduction.

- Size and Placement: Adjust the design to fit the dimensions of the item you are printing on. Ensure the design is sized correctly for the garment or product, and align it properly to avoid placement issues during the transfer.

Once your design is ready, it’s time to print it onto the transfer film.

Step 3: Printing and Applying the Adhesive Powder

Now that your design is ready, it’s time to print it. Load your transfer film into the DTF printer and ensure that the settings are optimized for your material and design. Here’s how to proceed:

- Print the Design: Print your design onto the transfer film. Remember, you’ll need to print the design in reverse (mirror image) so it appears correctly when transferred to the fabric.

- Apply Adhesive Powder: After the design is printed, apply adhesive powder while the ink is still wet. The adhesive helps bond the ink to the fabric during the heat transfer process. Use a powder shaker to evenly distribute the powder across the entire design.

DTF transfer is the next step, as you’ll need to cure the adhesive powder to ensure it adheres well to the ink and fabric. This step is essential to achieving durable, high-quality prints.

Step 4: Curing the Design and Preparing for Transfer

Once the adhesive powder is applied, you need to cure the powder before moving on to the heat transfer process. Curing ensures that the adhesive bonds well with the design, making it durable and long-lasting. This step is typically done using a curing oven or heat press.

- Curing Powder: Place the printed transfer film in a curing oven or use your heat press to cure the adhesive powder. The temperature should be around 160-180°C (320-350°F) for 3-5 minutes.

- Testing the Print: Before transferring to your final product, it’s a good idea to conduct a test print on a small section of fabric. This ensures the design adheres properly and gives you a chance to make any necessary adjustments.

After curing, you’ll be ready to transfer the design onto your fabric.

Step 5: Transferring the Design onto the Material

Now comes the exciting part—transferring the design onto the fabric. The heat press is essential for this step, as it applies the right amount of heat and pressure to bond the design with the material.

- Heat Press Settings: Set your heat press to the appropriate temperature (usually between 320°F-350°F) and time (15-20 seconds) based on the fabric you’re using.

- Transfer Process: Place the cured transfer film onto the fabric with the printed side facing down. Apply the heat press and press firmly for the recommended time. Once the time is up, carefully peel the transfer film off, revealing the high-quality design on the fabric.

After transferring, inspect the print to make sure it’s smooth and vibrant. If necessary, you can re-press the design to ensure it’s fully bonded.

Step 6: Scaling Your DTF Printing Business

Once you’ve mastered the process, you can start scaling your DTF printing business. Here are a few ways to expand:

- Increasing Production: Invest in additional printers and heat presses to increase production capacity. Automating some steps, like powder application, can further speed up the process.

- Expanding Product Range: Don’t limit yourself to just t-shirts. DTF printing is perfect for custom hoodies, bags, hats, and even promotional items like tote bags and drinkware.

- Marketing and Sales: Create an online store on platforms like Shopify or Etsy to sell your custom prints. Use social media to showcase your products and build a following.

The flexibility of DTF printing allows you to tap into various markets, from custom clothing for local businesses to personalized merchandise for influencers and events.

Conclusion

Mastering DTF printing can be a game-changer for your custom apparel business. With the right setup, preparation, and printing process, you can produce high-quality, vibrant designs on a variety of materials.

The versatility, cost-effectiveness, and scalability of DTF printing make it an excellent business opportunity in 2025 and beyond.

By following these steps and continuously improving your workflow, you can build a successful DTF printing business that meets the growing demand for custom products.

Whether you’re printing small batches or expanding your offerings, DTF printing provides the tools and flexibility to succeed in the custom apparel market.